Spotlights

Naturbeads

Translating to scale: continuous production of biodegradable microcapsules

Microcapsules are a particular type of microplastic, used in a wide range of applications from drug delivery to fragrance release in personal care products to controlled release of nutrients in agriculture. The vast majority are manufactured using non-biodegradable polymers obtained from non-renewable sources. After use, they are released into waterways and soil, with mounting evidence of their adverse effects on both the environment and human food chain. As a consequence, there is growing legislation around the world limiting or banning their use. The market for microcapsules is also substantial, estimated at USD 13.90 billion in 2024, recognising the key functions they provide to products. As such, they cannot be simply eliminated from products, putting pressure on manufactures to identify a more environmentally sustainable alternative.

The SCHEMA Hub is responding to this pressing need from industry with a collaborative R&D project between researchers at the University of Bath and Naturbeads Ltd. to develop innovative continuous manufacturing processes, explore industrially relevant microcapsule payloads, and ensure the technology is ready for integration into scaled-up manufacturing. The collaboration, which started in September 2025, focuses on polysaccharide-based microcapsules which have attracted considerable attention as an alternative as these are biodegradable, renewable, and biocompatible. However, current production methods for polysaccharide-based microcapsules employ complex preparation methods, such as multiple deposition steps or cross-linking, with little potential for scale-up.

Naturbeads facility

Cellulose Microspheres

Plastic Microspheres are used in cosmetics

The collaborative R&D project builds on a long-standing relationship between the partners: Naturbeads Ltd. was started in 2018 from the work of Professors Janet Scott and Davide Mattia at the University of Bath to manufacture biodegradable cellulose microspheres to replace plastic microspheres in a wide range of applications. Their first commercial plant will be starting large-scale manufacturing in Q4 2025. Professor Mattia, SCHEMA Hub Co-Investigator and Naturbeads CTO, is currently on industrial secondment with the company to help them scale and translate new technologies from lab to market.

Dr Guofan Xu has been recruited to lead the laboratory activities at Bath, with support from Prof. Mattia and Prof. Matthew Jones from the Department of Chemistry. Naturbeads Ltd. is providing advice, in the first stage of the project, on applications with the most impact in terms of plastic pollution reduction and the type of materials and reagents that are compatible with large scale manufacturing. In the second half of the project it is expected that Naturbeads will provide the academic team with access to its pilot plant to test the potential to scale-up the manufacturing of the biodegradable microcapsules developed.

Dr Giovanna Laudisio, Naturbeads CEO, said “As a University spin-off and a high-intesity R&D scale-up company, we very much value working with academic researchers and see innovation as key to the success of the company. We are happy to be part of the SCHEMA Hub and look forward to contributing to this exciting project with the University of Bath academic team”.

Scott Bader

Renewable Polyesters for Recyclable and Repairable Composite Resins

The global epoxy resin market was valued at USD 11 billion in 2023 (UK: USD 264 million in 2022), while the composites market reached USD 94 billion globally in 2022 (Europe: USD 19 billion). These materials are critical for applications such as wind turbine blades, but conventional thermoset epoxy resins pose significant challenges over their life-cycle: they are difficult to repair, remanufacture, and recycle, and the recovery of valuable reinforcing fibres like carbon fibre remains problematic.

Future energy generation depends on composite materials that are both high-performance, sustainable, and recyclable. The project aimed to overcome limitations of conventional epoxies by developing renewable polyesters that enable recyclability, repairability, and remanufacturing, while being compatible with existing manufacturing processes.

This project was delivered through a close collaboration between Dr Mati Concilio (University of Oxford) and Dr Stefan Lawrenson and Dr Steven Brown from Scott Bader, a leading composite materials manufacturer. From the outset, Scott Bader provided critical input on process safety and feedstock selection (e.g. starting material toxicity and compatibility) as well as manufacturing requirements (e.g. viscosity parameters), allowing for careful design of polyester resin materials.

Aims of the project:

- The design and synthesis of polyester resin matrices from commercially available, renewable feedstocks with no purification required.

- Compatibility with current resin manufacturing processes and equipment.

- Development of high-performance resins suitable for composite applications.

- Utilisation of polyester chemistry to facilitate dynamic exchange reactions and enable easier, low-energy recyclability and repair.

Outputs and impact from the project:

- A series of renewable polyesters with viscosities suitable for current resin processing methods – demonstrating potential for scaling up through Scott Bader’s industrial facilities.

- Developed resin formulations with competitive mechanical performance and low-energy recycling pathways – evaluated the chemistry and conditions needed for repair and reprocessing of the resins and determined their energy requirements.

- The project featured a researcher secondment to Scott Bader’s Wollaston site for technology transfer, material exchange, and industrially-relevant testing of promising resins.

- Senior R&D engagement, including Dr Stefan Lawrenson contributing to SCHEMA Hub conferences and providing insight into sustainable material design and manufacture.

- Instrumental in securing additional support through an EPSRC Impact Acceleration Account for follow-on research to widen applications and assess manufacturing feasibility.

This project highlights the value of academia–industry partnerships in addressing global sustainability challenges. The combination of academic innovation in polymer chemistry and Scott Bader’s industrial expertise and infrastructure facilitated the development of renewable resins that balance performance, sustainability, and manufacturability.

Valorisation of CO2 through hydrogenation to methanol

Global methanol production reached around 98 Mt/yr in 2021, however almost all of this was produced from fossil fuel sources (either natural gas or coal). The market is growing rapidly, with forecasts suggesting production could reach 500 Mt/yr by 2050 and the majority of this growth is expected to be from e-methanol. The transition away from fossil-based resources and increasing utilisation of renewable feedstocks means that around three quarters of this production could be accounted for by renewable methanol (e-methanol and bio-methanol).

Methanol is critically important as a platform for the chemicals industry; a highly versatile intermediate used for the manufacture of a broad range of products including plastics, adhesives, adsorbents, coatings, and solvents. Methanol is also becoming increasingly important as an energy vector, serving as an alternative fuel or fuel additive. E-methanol is produced by the hydrogenation of biogenic CO2 using green hydrogen, a process that requires efficient, selective, and robust catalysts. More broadly, the chemical industry depends on catalysis for more than 90% of industrial chemical processes, making catalyst development crucial for future sustainable chemicals manufacturing.

Methanol synthesis is a mature technology; CO2 hydrogenation to methanol has been the subject of much research. The reaction of converting CO2 to methanol is an exothermic process so high pressures and low temperatures are preferred; however, the stability of CO2 means that higher than desired temperatures are often needed to convert a sufficient amount. This often means that there is competition with the reverse water gas shift which transforms CO2 into CO. The complexity of the tricomponent nature of the CuO-ZnO-Al2O3 catalyst used commercially still leaves much to understand on the active component, allowing for further development. This project aims to determine catalyst structure-performance relationships and use novel synthesis techniques that can enhance desirable characteristics. Greater insight into the mechanistic pathway through advanced operando techniques will allow for a deep understanding of how the catalyst works and enable the design of catalysts with high performance. This would lead to the ultimate goal of producing catalysts that have a greater selectivity to methanol allowing for greater productivity on an industrial scale.

Methanol is traditionally made from syngas, which is produced by steam reforming of natural gas at high purity. The production of ‘eMethanol’ from biogenic CO2 and green hydrogen will introduce increased complexity due to the addition of contaminants in the synthesis feed. In alignment with objectives set by Topsoe, selected catalysts synthesised in Cardiff will be tested on an industrial scale using reaction feeds mirroring those that would be used in the commercial synthesis of eMethanol. This will probe catalyst stability over time and in the presence of possible poisons and inhibitors.

ILS High Throughput Reactor where catalyst testing is performed

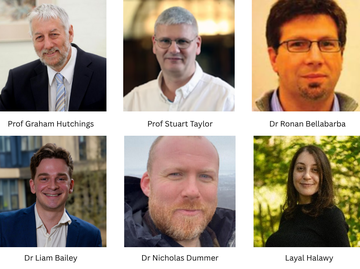

Topsoe and Cardiff University staff

Cardiff Catalysis Institute

Topsoe is a global leader in catalysis and process technology, especially known for its advanced solutions in methanol production. More than 65 methanol plants worldwide use Topsoe’s catalysts and technologies, giving the company a strong presence in this market.

Traditionally, methanol is made by steam reforming natural gas to create synthesis gas (syngas), which is then converted into methanol using catalysts. Topsoe’s methanol catalysts are designed for high performance, selectivity, and stability, ensuring efficient conversion of syngas into methanol. Methanol can also be produced from green hydrogen and biogenic CO₂, which helps make chemical processes more sustainable. Topsoe offers specialized catalysts, such as MK-417 SUSTAINTM, that are optimized for using CO₂ as a feedstock. These catalysts are designed for selectivity, stability, and durability in Topsoe’s eMethanol process, which uses green hydrogen as it is produced by an electrolyzer and can adapt to fluctuations in hydrogen availability, maintaining production even when supply is restricted. Since biogenic CO₂ is limited, eMethanol plants will be built as prefabricated ModuLiteTM units, with capacities ranging from 150 to 600 metric tons per day (MTPD).

Topsoe’s leading position in the market is supported by ongoing investment in collaborative research and development with academic partners to advance catalyst technologies.

This project is delivered by the research team led by Prof. Graham Hutchings from Cardiff University in close collaboration with Dr Ronan Bellabarba, an industrial scientist and R&D lead from TOPSOE. The research involves aspects of experimentation, process optimisation, and computational modelling to design, synthesise, evaluate the performance of new catalysts for CO2 hydrogenation, ensuring they are industrially relevant for applications in both renewable methanol synthesis and other valuable chemical transformations.

The partnership between Cardiff University and TOPSOE is implemented through regular monthly meetings to monitor the progress of the project, exchange knowledge and ideas. This helps identify key areas in which more research and development is required and help facilitate the development of technologies from lab-scale to industrial scale. TOPSOE will send samples of their specialized catalysts to be benchmarked against new technology, and catalysts synthesised in the Cardiff Catalysis Institute labs will also be sent for testing at the TOPSOE facilities, which will then enable students involved in this project to receive industrially relevant training through placement programmes.